Operating principle

The mixture of solid and liquid is distributed uniformly&quickly in centrifuge drum by feeding tube and distributing evenly through the distributing disk. acting on the centrifugal position. Liquid-solid mixed fluid intercept the solid phase through the fitter to filter out the liquid phase. Centrifuge continues to feed until full. Then stop. Solid cake is rinsed and purified when the process requires. And the rinsing liquid is filtered out meanwhile. Centrifuge further filter until the separation requirements are met.

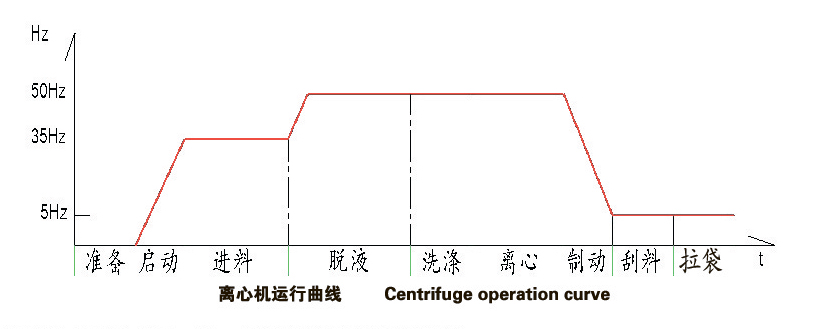

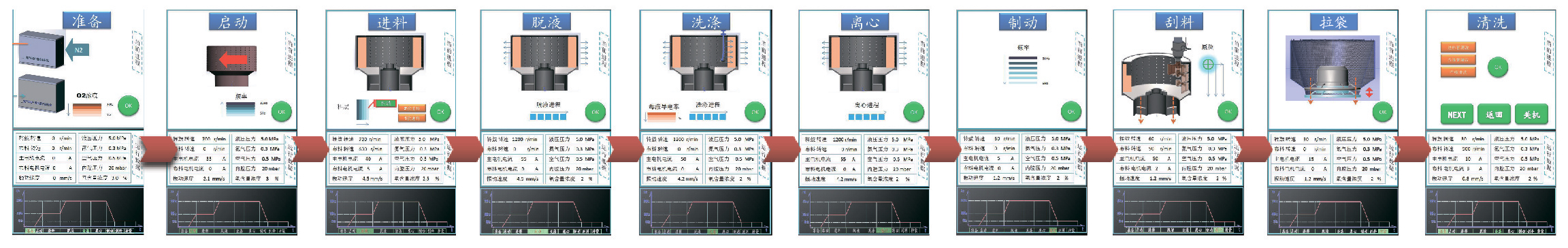

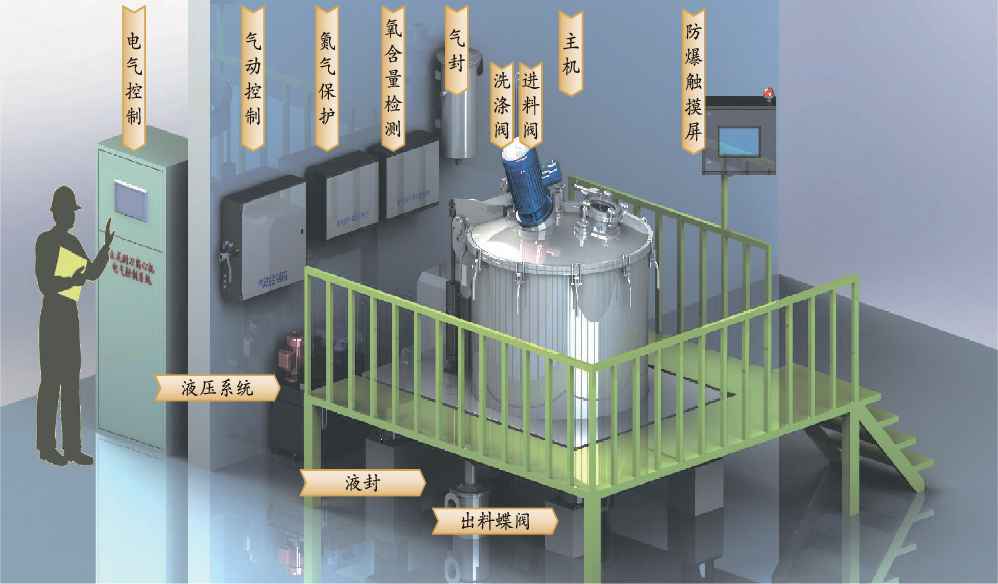

Control Process

The operation of centrifuge is controlled by PLC. The system runs automatically according to the preset program. Different centrifuges have corresponding operating parameters or range of adjustment.

In order to meet the requirements of separation. appropriate operation parameters are set for specific conditions

in debugging and subsequent operation. The control system can automatically repair or protect the overload in the actual operation.

Automatic control system controls centrifuge mainframe, hydraulic system, pneumatic system, N2 protection system,and pump, valve, material conveying system related with centrifuge, etc.

Operation and control process of centrifuge

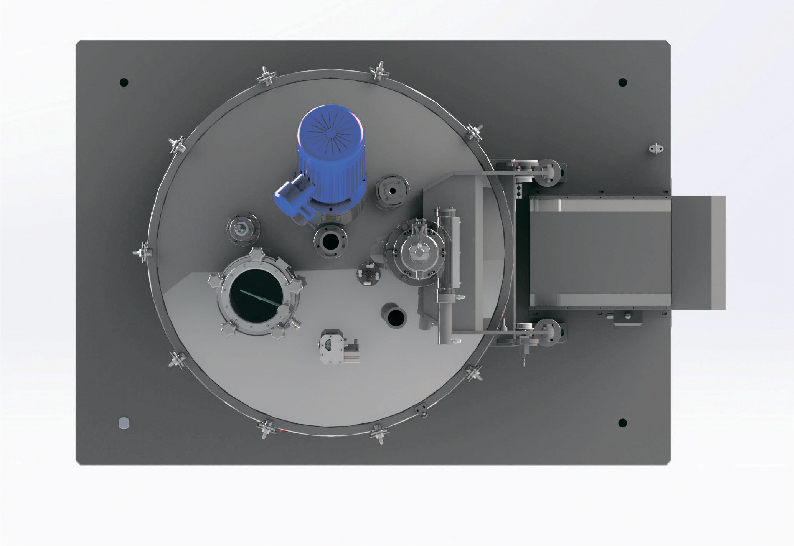

LGZ plant scraper discharge centrifuge

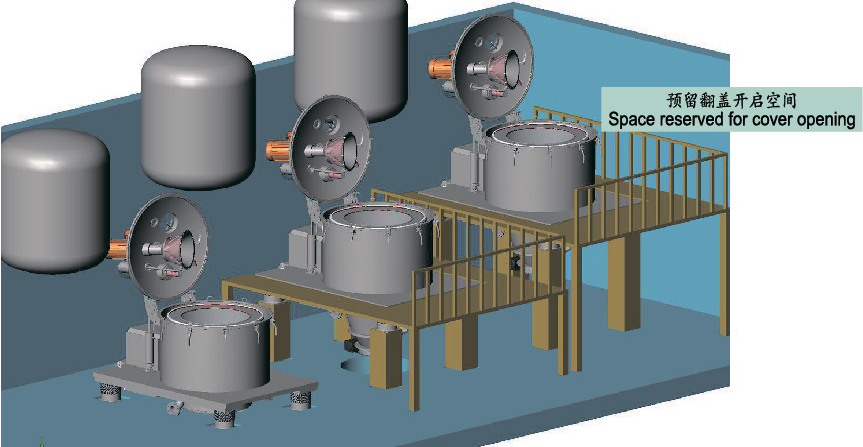

LGZ Top cover diagram

System integration

XINGYI Automatic and intelligent control, remote control and unmanned workshop

XINGYI Fully enclosed, satisfying environmental requirement on closed loop production

Personal configuration

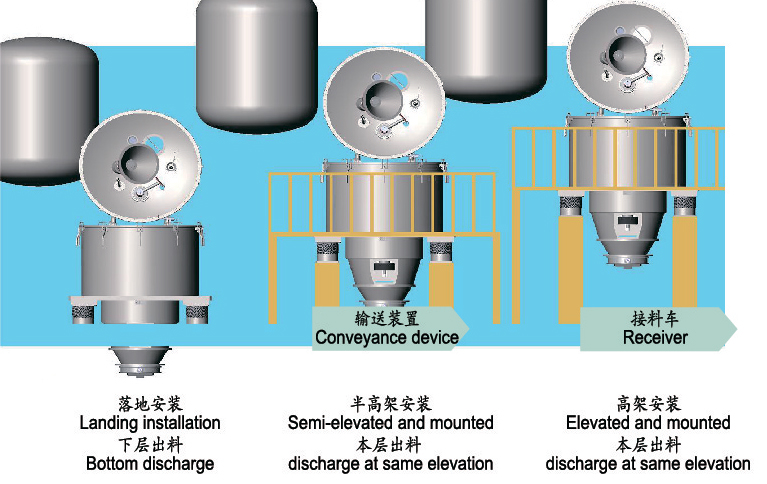

Installation

u Safety: satisfy requirements on dynamic and static loading capacity, shock absorption and isolation, operation and maintenance

u Convenience: Meet the convenience of operation and maintenance

u Economical: Meet the rationality of process chain, reduce logistics turnover link and reduce operation cost

u Provide installation foundation draws and related technical supports.

Main features

u Flat plant structure, liquid damping, no foundation mounting

u Large or fully hinged cover form

u declining feeding disk .Adjustable feed device to improve distribution balance

u Removal of residual filter cake by top bag pulling device

u Setting material thickness+Layer detection+N secondary feed. Ensure fitter cake thickness

u Automatic repair of filter cake imbalance+Over-vibration standby protection

u Atomization washing. Washing quantitative control. Clearance/pulse washing. Detection of conductivity of washing filtrate+Liquid output conversion.

u High precision drum (machining and balance), high separation factor, improved separation efficiency

u Set Spindle Seal, scraper Shaft Seal, feed disk Seal.Axial seal pressure higher than inner cavity 20mbar. Exhaust gas orderly emission.

u Joint drive belt

u Built-in speed sensor

u External oil supplement (manual/automatic)

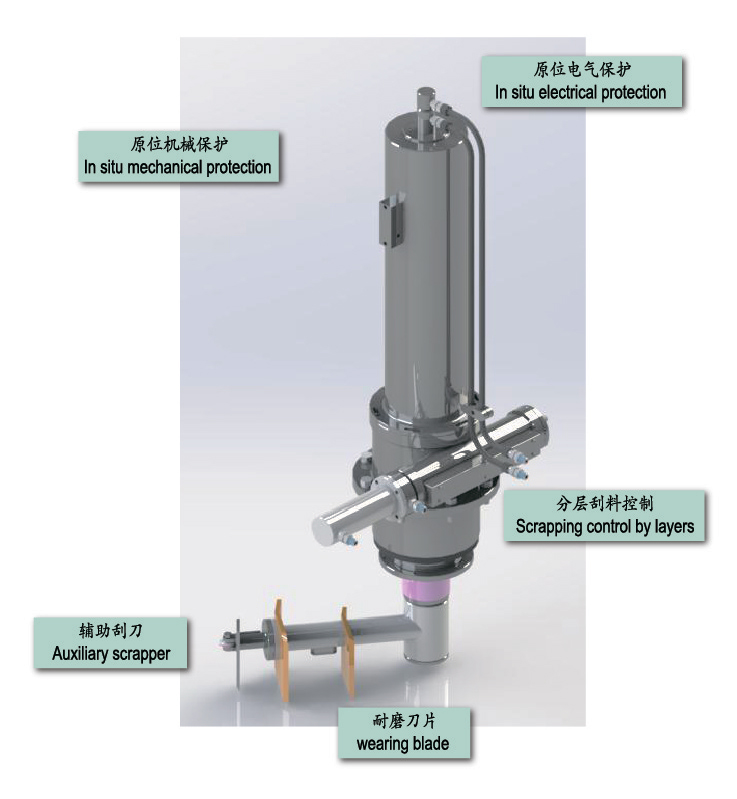

u Digital control stepless layer scraper, plug rotation automatic repair

u Scraper blade wear-resistance and pollution-proof design

u Fully enclosed hydraulic station, Stainless steel hydraulic tank

u Automatic cleaning program

u Fully enclosed system satisfying specification of pharma production

u Computer, mobile phone APP remote monitoring system

u Multiple layers of protection

Over-vibration protection, cover opening and closing protection

Motor overload protection, Material level protection, scrapper normal position protection. In situ protection of bag pulling support. Process linkage, Mechanical and electrical protection.

N2 protection, Electrostatic grounding protection.

Overhaul lock protection.

Fault diagnosis and standby Protection

Discharge control

u Stepless stratification scrapping (0-100% adjustable)

u Discharge plugging automatic repair

u Normal position protection

u The feed disk prevents the raw material from piling up

u Scrapper blade of wear-resistance and pollution-proof design

u Auxiliary scraper(applicable for LGZ)

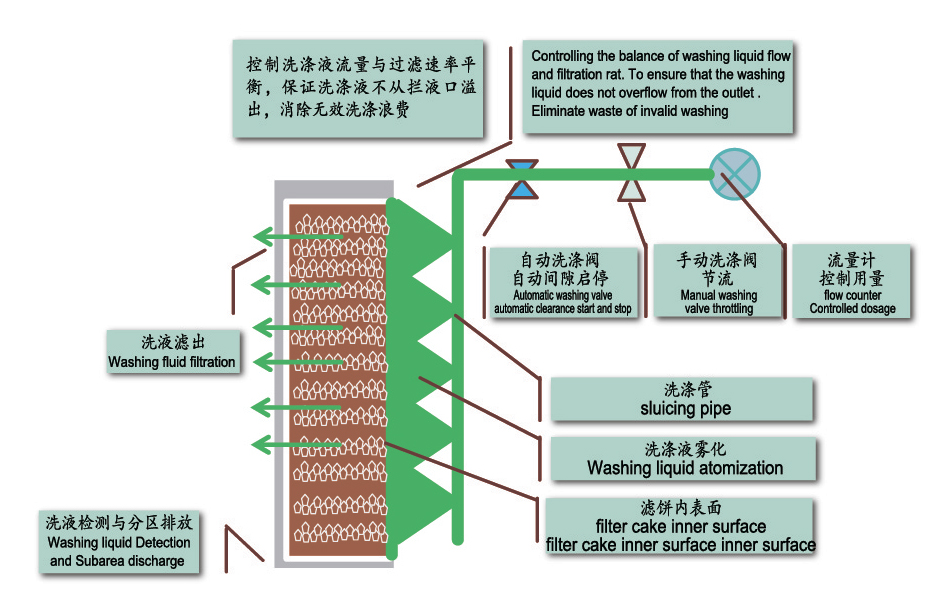

Washing control

u Washing flow control (manual controlled valve/flow meter and automatic valve

u Intermittent/pulse washing

u Washing liquid quantity /Timing washing

u Detection of conductivity of washing filtrate+Liquid output conversion

u Atomization washing

System configuration

u Main engine of centrifuge

u Hydraulic system

u Pneumatic control system

u Electrical control system

u Ex-proof operating box / Ex-proof touch screen

u N2 protection一oxygen content detection

u N2 protection一N2 replacement

u Liquid seal

u Air seal

u Discharge valve, feed valve, washing valve

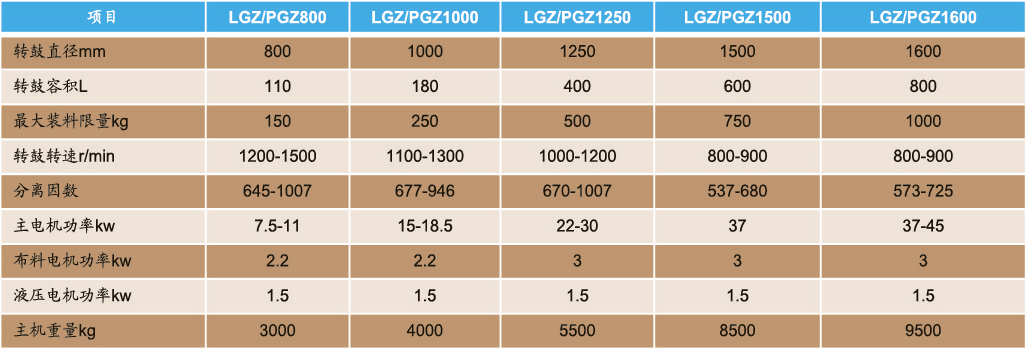

Technical parameter

LGZ Outline drawing

Connection interfaces

1 Feed inlet

2 Washing inlet

3 Liquid discharge

4 Solid discharg

5 N2 inlet

6 Exhaust air outlet

7 Shaft seal air inlet/outlet and pressure testing port

8 Material thickness control

9 Manhole and cleaning

10 Hydraulic integrated interface