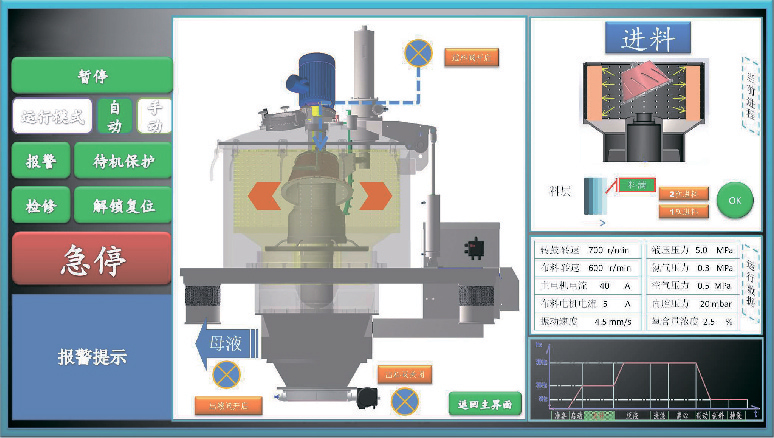

Operation process of the centrifuge is fully automatic controllable via PLC program in a single unit control way or integrated control of multiple sets. By applying technologies of distributed control system,internet of things and fault diagnosis technology to improve automation level and intelligent control Ievel of the centrifuge system

> Automatic control technology for the centrifuge

PLC programmable, control requirements can be input and output in digital or analogue way including those on time,control logic,sequence control, timing, counting, calculating, self一lock and interlock for realizing centrifuge control.

- PLC program control, one key start-up,fully automatic running

- Automatic feeding,material layer detection, overload protection and automatic repair

- Over vibration protection and automatic repair+standby protection

- Pulse washing plus filtrate conductivity detection+filtrate conversion

- Step-less adjustable scrapping by layers, combining with function of overload protection and automatic restoration,suitable for hard material

- N2 protection automatic program control

- One key restoration to defauIt setting of the factory

- Two-level password design,i.e.operation level and configuration level

- Parameter setting, changing and optimizing for separation and filtration process

- Storage and access to process parameter of various products

- Computer remote monitoring and mobile APP monitoring

> Safety protection

Realize protection and trouble alarming via automatic

control process, sensor, mechanical and electrical device

- Maintenance lockout

- Overload protection

- Mechanical and eIectrical interlock protection

- Alarm function

- Fault diagnosis prompt+history record search

> Distributed control system(DCS)

Single unit control or distributed control of multiple units,to operate, monitor and set parameter of the centrifuge remotely in the central control room, integrated control of the process section(feeding,washing, discharging,main motor running,alarming)

-

Linkage controI with reIevant equipment: Perform linkage control over feeder pump,washing pump and filtering cake conveyance system etc.

-

Remote controI and remote fauIt diagnosis and troubleshooting

-

Remote program updates

-

Remote monitoring

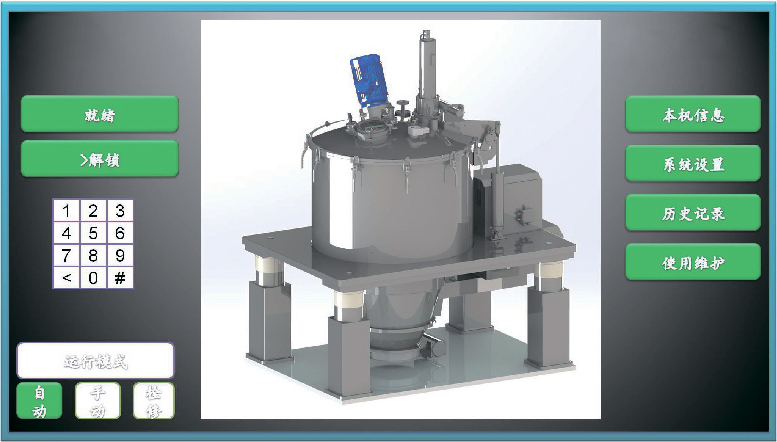

> User interface

-

Access configuration

-

About the unit

-

Alarm database

-

Operation data search

-

Operation modes setting and separation parameter setting

-

Application technologies database

-

Fault diagnosis prompt

-

User’s instruction and maintenance guideline

-

Dynamic display

-

Automatic and manual mode switch

-

Real-time display of operation data

-

Maintenance lockout