Operating principle

The solid and liquid mixture will be fed into the centrifuge drum via feed pipe and distributed evenly all over the inner wall of the drum, at where the solid phase will be retained by filter disk under effect of centrifuge field while liquid phase discharged out of the filtration process. The feeding process will keep going on until the centrifuge drum is fully charged. Filtering cake will be rinsed and purified as necessary and rinsing water will be discharged meanwhile. Then, there comes a further dehydration process till effective separation is achieved. In process of full or moderate speed running, the scrapper will peel off most of the filtering cake and one entire working cycle completed.

GKH' s operation is based on siphon principle, designed with filtering power, resulting in lower water content of filtering cake.

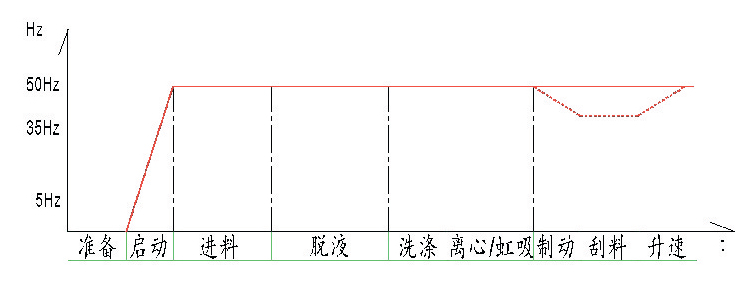

Control process

Centrifuge operation is PLC controlled, where the system will run preset program automatically with operation parameters or their adjustment range varying for different models/types of unit. Appropriate operation parameters will be defined and set for specific working condition based on results of testing/commissioning and subsequent operation in the aim to achieve effective separation.

The control system will fix or protect from overload in process of operation automatically.

The automatic control system controls main engine, hydraulic system, pneumatic system, N2 protection system, valves as well as pumps, valves and material conveyance system etc. relating to the centrifuge.

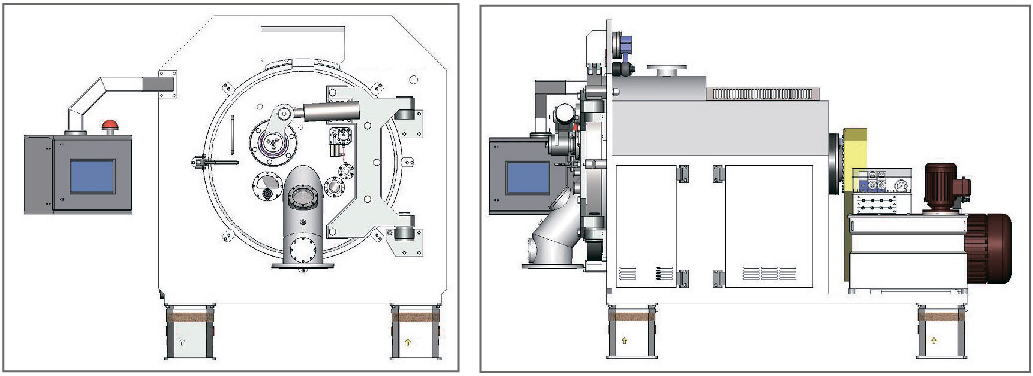

System integration and installation

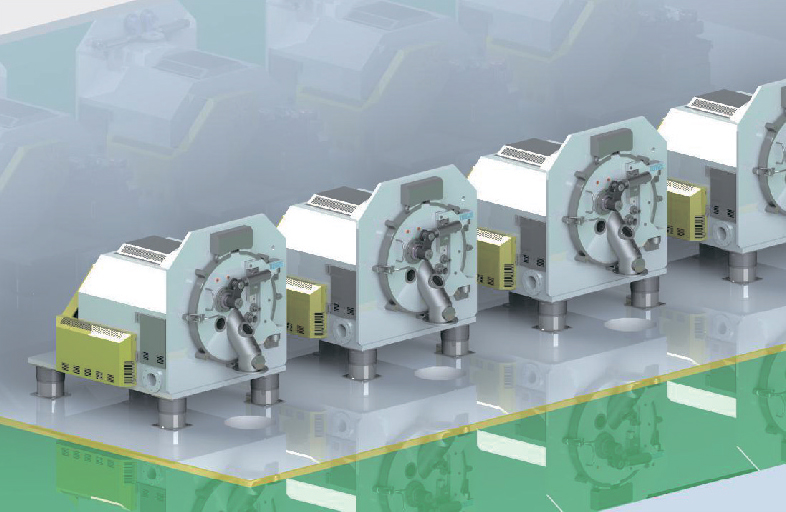

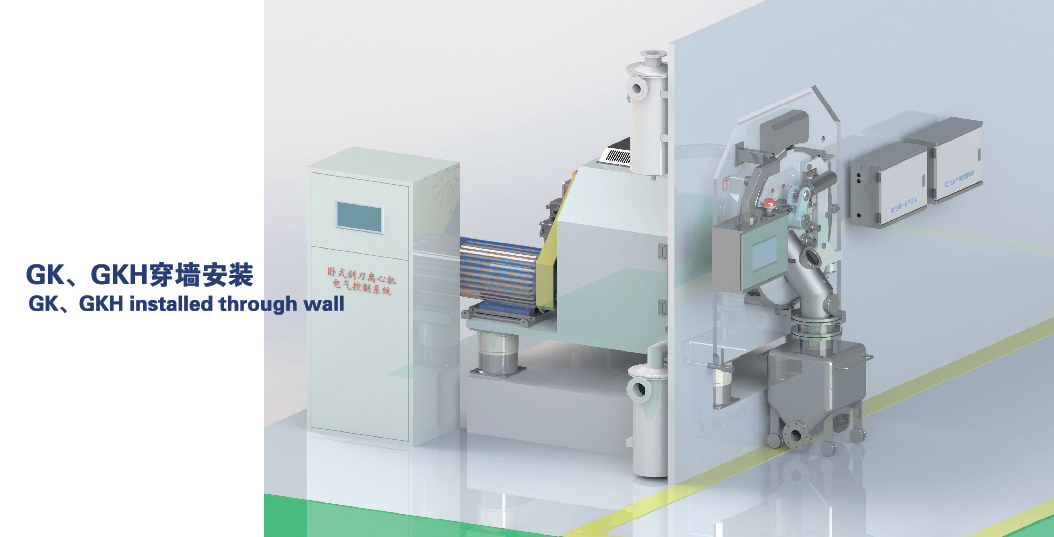

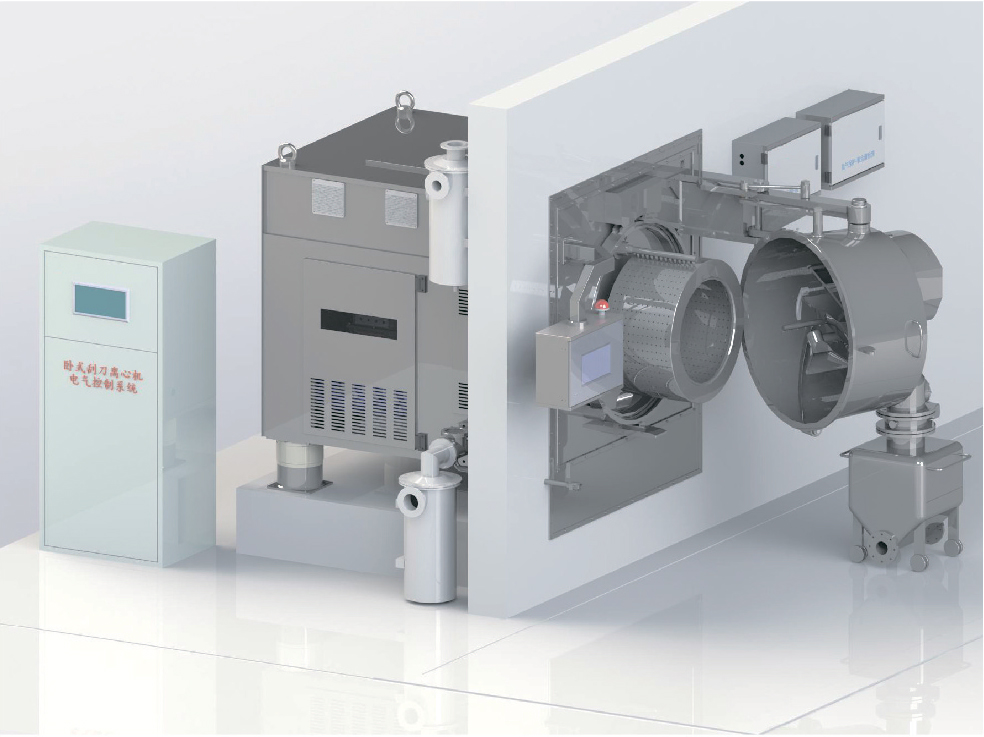

GK whole system installation

Whole system floor mounted: with discharge port connected to filtering cake conveyance system at next level I

Whole system elevated and installed: space reserved at same level for discharge and filtering cake conveyance

Technical parameter

Main feature

u With platform base, liquid damper, floor mounted without needing plinths

u Fully or sliding openable cover, hydraulic locking system

u Duckbilled distributer, with adjustable feeding device, improving balance of material distributed.

u Air backflow or spiral hob equipped to clean and clear off any residue filtration cake;

u Able to preset and detect thickness of the feedstock and to make several times of feed supplements as needed for ensuring thickness of the filtration cake.

u Auto fix of unbalanced filtration cake plus over-vibration standby protection

u Atomization washing, washing flow control, intermittent/pulse washing,

u High or moderate speed of scrapping (speed programmable)

u Rinsing water and filtrate conductivity detection and conversion

u Filtrate sampling port

u High precision drum (digital machining and high precision balance), high separation factor, improved separation efficiency

u Designed with main shaft seal, scrapper shaft seal and distribution shaft seal, pressure in shaft seal is 20mbar higher than that of inner chamber, organized emission of exhaust gas.

u Joint transmission belt

u Speed sensor

u Automatic bearing oil recharging device

u External oil supplement (manual/automatic)

u Stepless stratification scrapping, auto fix of locked rotor, scraper blade wear-resistance and pollution-proof design

u Fully enclosed hydraulic station, stainless steel oil tank

u Automatic cleaning program

u Fully enclosed system satisfying specification of pharma production

u PC and mobile App for remote monitoring

Multiple layers of protection: Over-vibration protection, cover opening and closing protection, motor overload protection, feedstock level detection and overload protection, scrapper normal position protection, job sequence linkage plus mechanical and electrical protection, N2 protection, static grounding protection, trouble-shooting and standby protection, locking protection for maintenance

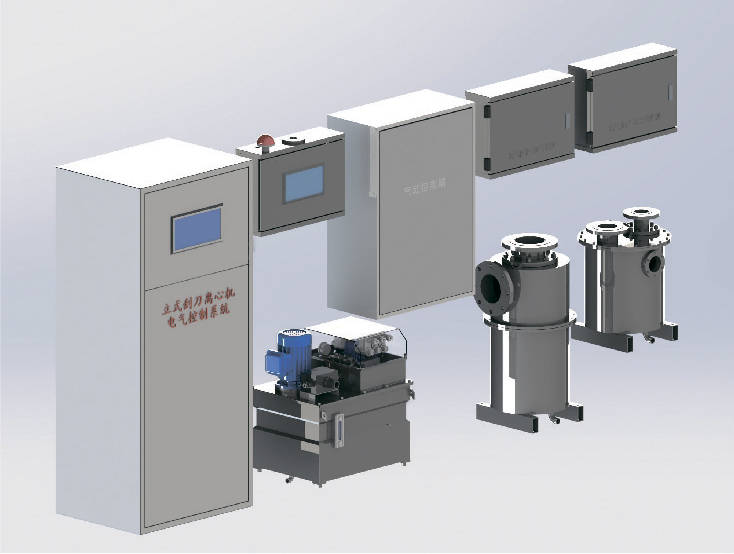

System configuration

u Main engine

u Hydraulic system

u Electrical control system

u Ex-proof operation cabinet/Ex-proof touch screen

u N2 protection and oxygen content detection device

u N2 protection and N2 replacement

u Liquid seal

u Air seal

u Mother liquor sampling tee

u Filtering cake transit silo

u Discharge valve, feed valve and washing valve

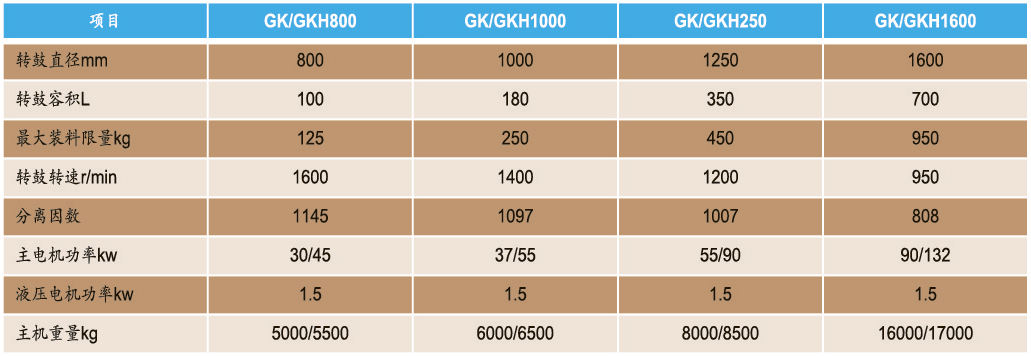

Technical parameter

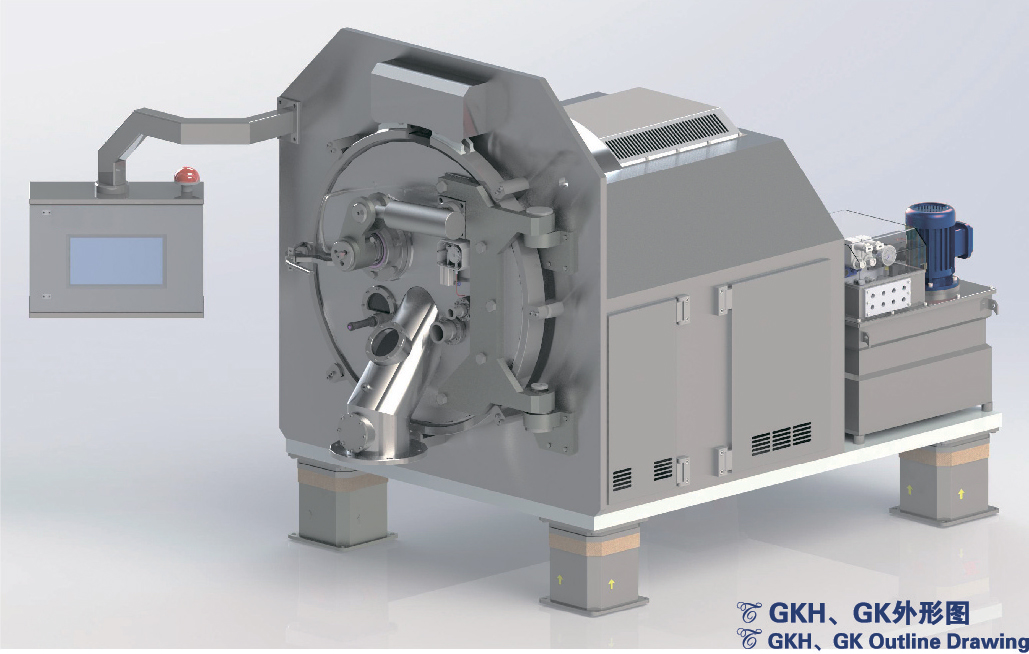

GKH Outline Drawing